What You Need to Know Before Trying Zintilon Sinker EDM Machining Service

Sinker EDM is a specialized manufacturing process that excels in creating intricate and precise parts from hard materials. While the process is unconventional, Zintilon, a reputable machine shop in China, offers expert sinker EDM services. They leverage state-of-the-art technology and skilled technicians to deliver high-quality components across various industries.

This article explores Zintilon’s sinker EDM machining services, providing the advantages of this process and its alternatives.

What is EDM Sinker Machining at Zintilon

This section introduces Zintilon’s expertise in sinker EDM machining, outlining the precision and capabilities of this advanced manufacturing process.

Sinker EDM Machining

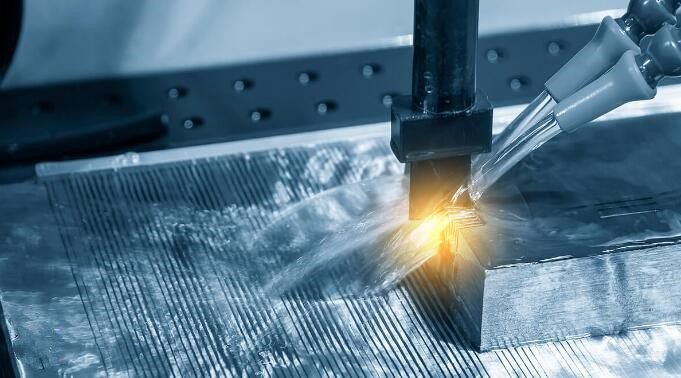

Zintilon sinker EDM machining is a precision manufacturing process that uses electrical discharges and sparks to remove components from a workpiece. Unlike other machining operations, this process is more commonly used to machine hardened materials, such as titanium, tungsten carbide, and hardened steel.

EDM is a non-conventional subtractive manufacturing method because of its unique method of removing parts from a workpiece. The process uses a specially shaped electrode, called the sinker and dielectric fluid, to create the desired features on the metal surface. The electrode and the workpiece are submerged in the dielectric fluid, which helps control the sparking process and flush away eroded material.

Machining shops leverage sinker EDM’s capability to machine hardened materials that traditional methods find challenging. Moreover, it is suitable for creating complex structures and intricate and detailed cavities. Still, regardless of the design complexities, it maintains a precision standard and fabricates parts with fine surface finishes. Consequently, it is the go-to process for creating casting molds, producing dies, and crafting parts with complex geometries.

Zintilon

Zintilon is a leading machine shop based in China known for providing premium machining services. Its die-sinking EDM services produce highly precise and intricate components for various industries. The company’s expertise in EDM allows it to handle complex projects, ensuring high-quality outcomes for its clients.

Zintilon’s facilities boast advanced, state-of-the-art machinery and skilled technicians who ensure that each project meets the highest standards of precision and quality. The company is dedicated to providing customized solutions to meet the specific needs of its customers.

Pros of Sinker EDM Machining

Sinker EDM provides unique advantages to parts fabrication. Below are some of its benefits.

Precision and Accuracy

Sinker EDM machining offers exceptional precision and can achieve tight tolerances specifications for complex fabrications. The process produces parts with complex geometries that are difficult or impossible to achieve with conventional machining methods. This precision makes it ideal for industries requiring high accuracy, such as aerospace, medical, and mold making.

Ability to Machine Hard Materials

One of the most significant advantages of sinker EDM is its ability to machine hard materials that are challenging to cut using traditional machining methods. Since the process does not necessarily use cutting tools to machine these metals, it can handle them. Sinker EDM suits machining materials like hardened steel, carbide, titanium, and exotic alloys, which can be easily machined with EDM. This advantage makes EDM the go-to process for tool and die creation.

No Mechanical Stresses

Unlike many conventional manufacturing techniques, sinker EDM is a non-contact process. This attribute means no physical force is applied directly to the workpiece during machining. Therefore, the workpiece experiences minimal mechanical stress, preventing common defects like deformation, warping, or damage to delicate parts. Consequently, sinker EDM suits the creation of fragile or thin-walled components.

Excellent Surface Finish

The high precision and tolerance specifications of sinker EDM allow it to achieve smooth surface finishes, reducing the need for additional finishing processes. In addition, producing fine finishes without secondary operations reduces production time and costs. Indeed, it is a slow process, but this attribute helps enhance the overall efficiency of the manufacturing process.

Versatility in Complex Shapes

As it suits creating parts with excellent surface finishes, sinker EDM offers significant versatility in creating complex shapes and designs. The process suits the making of deep cavities, sharp internal corners, and intricate contours. This versatility is particularly beneficial in mold and die-making, requiring detailed and complex features.

Automation and Repetition

Sinker EDM supports automation, often integrating CNC (Computer Numerical Control) technology into EDM machines. The automation of these devices allows the machines to run almost independently, allowing for consistent and repeatable part production. Therefore, sinker EDM can ensure the manufacturing of identical components that can be produced repeatedly with high accuracy. This feature suggests that sinker EDM will suit the mass production of parts without compromising quality control.

Alternatives for Sinker EDM Machining

Indeed, sinker EDM is an effective process, offering machinists and OEMs vast capabilities. However, there are various alternatives. This section will discuss two popular and equally versatile alternatives to sinker EDM: metal casting and CNC machining.

Metal Casting

Metal casting involves various manufacturing processes that heat metal into molten at high temperatures. The liquefied metal is then forced into a pre-designed mold cavity under high pressure, where it cools and solidifies into the desired shape. The process suits fabricating structures and components with complex structures.

This process can be performed in various ways. Let’s examine some of the common types.

Sand Casting

As the name suggests, sand casting involves using a mold made from a sand mixture into which the molten metal is poured. Like other forms of metal casting, it suits creating parts with complex shapes, allowing the creation of cost-effective structures. However, it may create parts with poor surface finishes and lower dimensional accuracy.

Die Casting

Die casting is one of the most common forms of metal casting. It uses a metal mold and high pressure to inject molten metal, resulting in parts with fine details and a smooth surface finish. Die casting creates parts with high precision, maintaining intended tolerance specifications. Consequently, it offers applications to various industries, including automotive and consumer electronics.

Permanent Mold Casting

Permanent mold casting is similar to die casting, using a high-pressure metal mold. However, the casting mold is reusable for multiple fabrications. Still, it produces consistent parts, though the application could be improved when creating complex shapes and geometries.

CNC Machining

CNC (Computer Numerical Control) machining is a more sophisticated process. Like sinker EDM, it is a subtractive manufacturing process. However, in this case, machinists use pre-programmed computer software to control the movement of machinery and cutting tools to shape a workpiece. Consequently, the method is known for its high precision and versatility, allowing for the production of both simple and complex parts.

Like metal casting, CNC machining operations are of various forms.

CNC Milling

Milling operations involve using rotating cutting tools to remove material from a fixed workpiece. It is one of the most common CNC machining operations because it is versatile for creating various shapes, slots, holes, and contours. Consequently, it offers applications in various industries, including aerospace, automotive, and manufacturing, for producing complex components.

CNC Turning

CNC turning is similar to milling, as they share the same fundamentals. However, the most significant distinction is that turning uses a single-point fixed cutting tool – often a lathe – to cut against a rotating workpiece. Consequently, it is known for creating rounded shapes and structures. Therefore, it has more limited applications compared to milling. Still, it offers vast applications in the fabrication of shafts, rods, screws, and other round parts in industries like automotive, aerospace, and other manufacturing industries.

CNC Drilling

Drilling involves creating holes in the workpiece using rotating drill bits, often combined with milling and turning operations. Its application mainly involves creating precise holes in a workpiece for various industries. These holes often ensure precise fastening for assembling parts manufactured from other processes.

Conclusion

Sinker EDM machining is an excellent choice for fabricating complex geometries, especially using hardened materials. Zintilon is an expert in offering these services, provided your project requires sinker EDM applications. However, other manufacturing processes may be suitable for fabricating your parts. The choice of technique depends on your project and material choice. Therefore, it is best to understand each process to make an informed decision on what best suits your fabrication.